IC Necklace

21 Feb 2025We love making electronic jewellery. We especially like building interactive electronic jewellery. So I figured that another category to explore would be non-electronic interactive jewellery.

A cut-down version of the simsim pendant could work, just a vial of mercury around your neck. The older style of mercury tilt switches, which held a substantial quantity of mercury, were indeed fun to play with, although perhaps straying a bit from the traditional virtues of jewellery.

You can get various oil-and-water trinkets and keychains that follow a similar principle and replace the toxic metal with colourful alternatives. The technology seems ripe for turning into interactive jewellery.

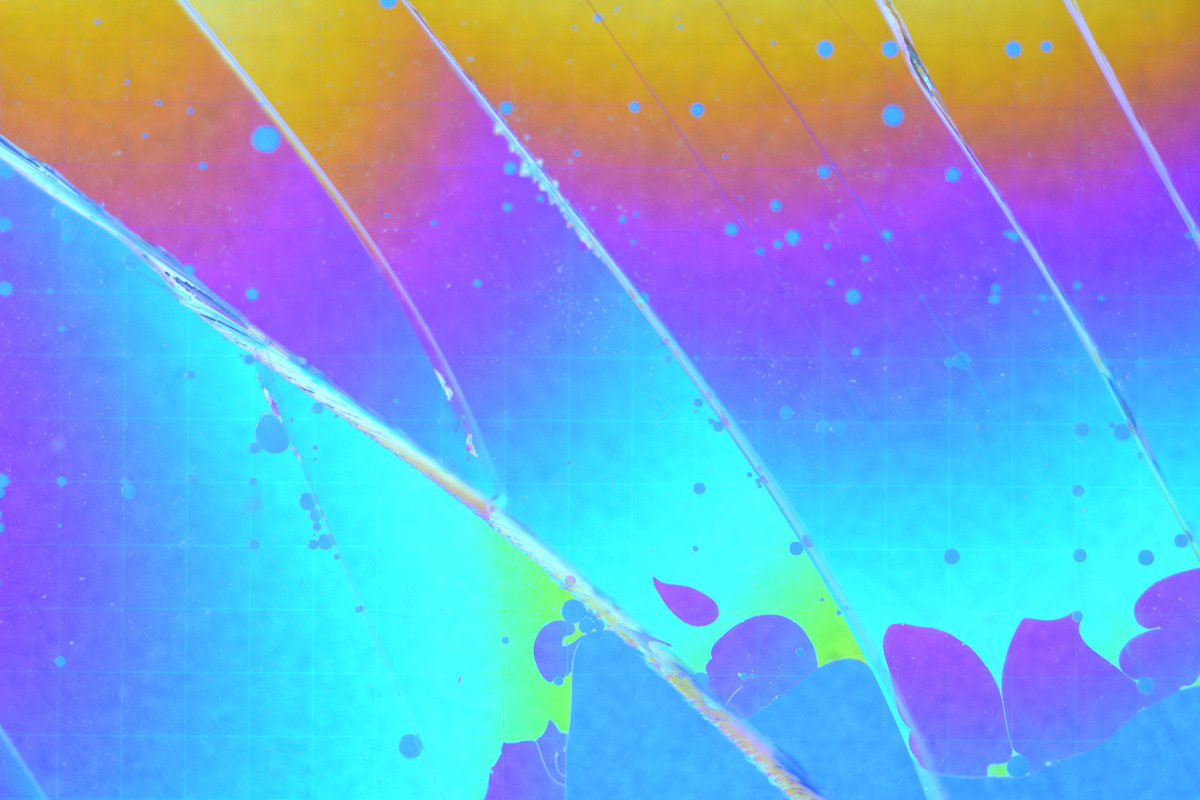

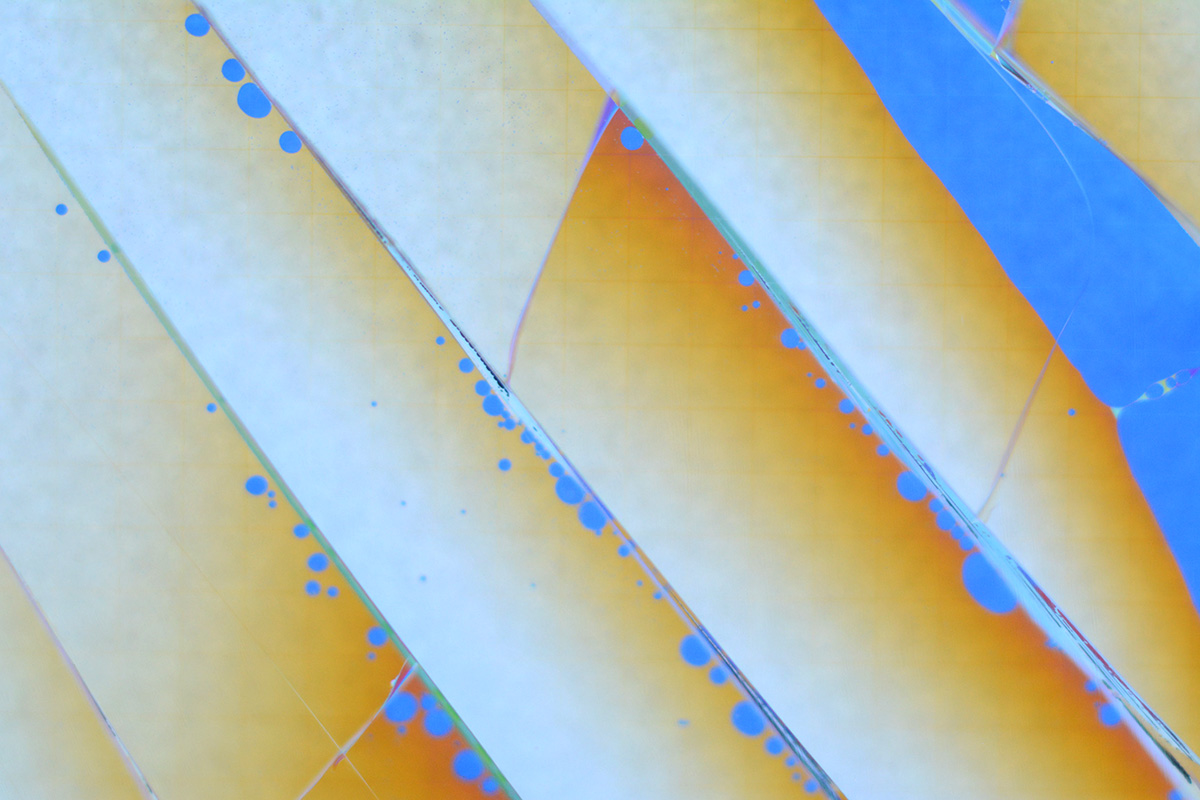

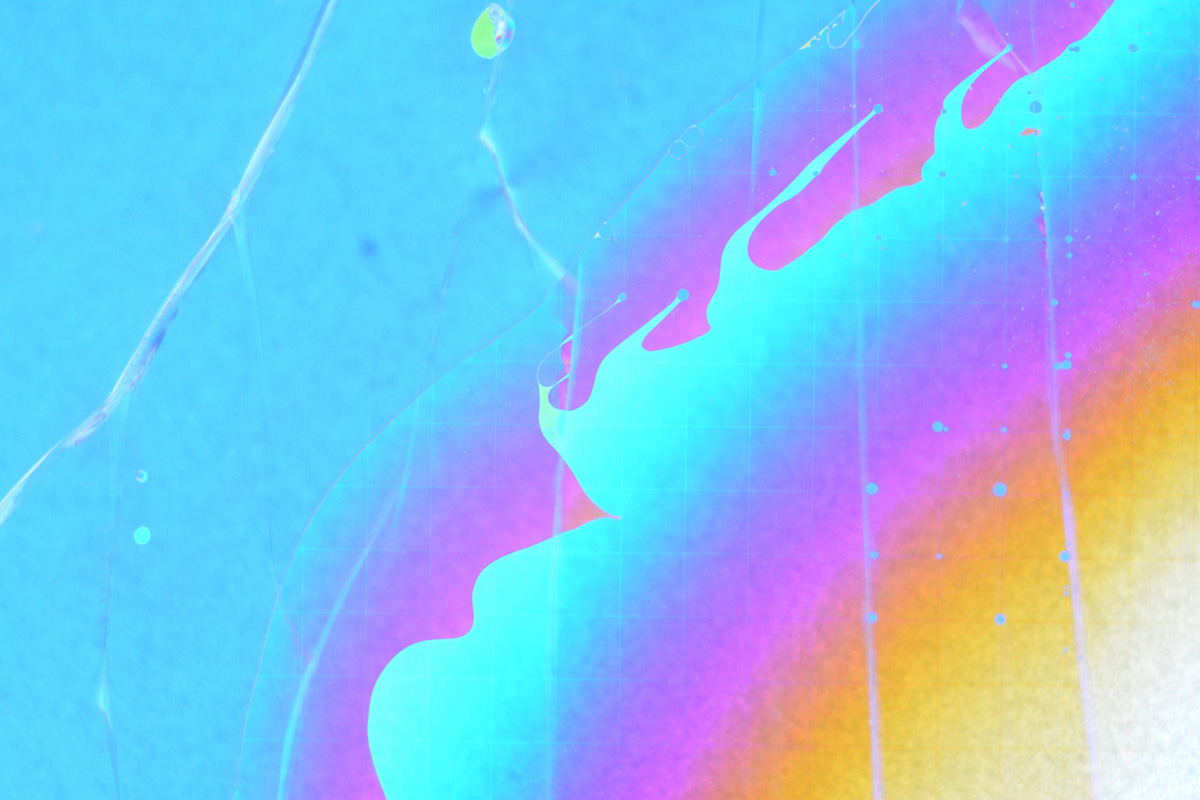

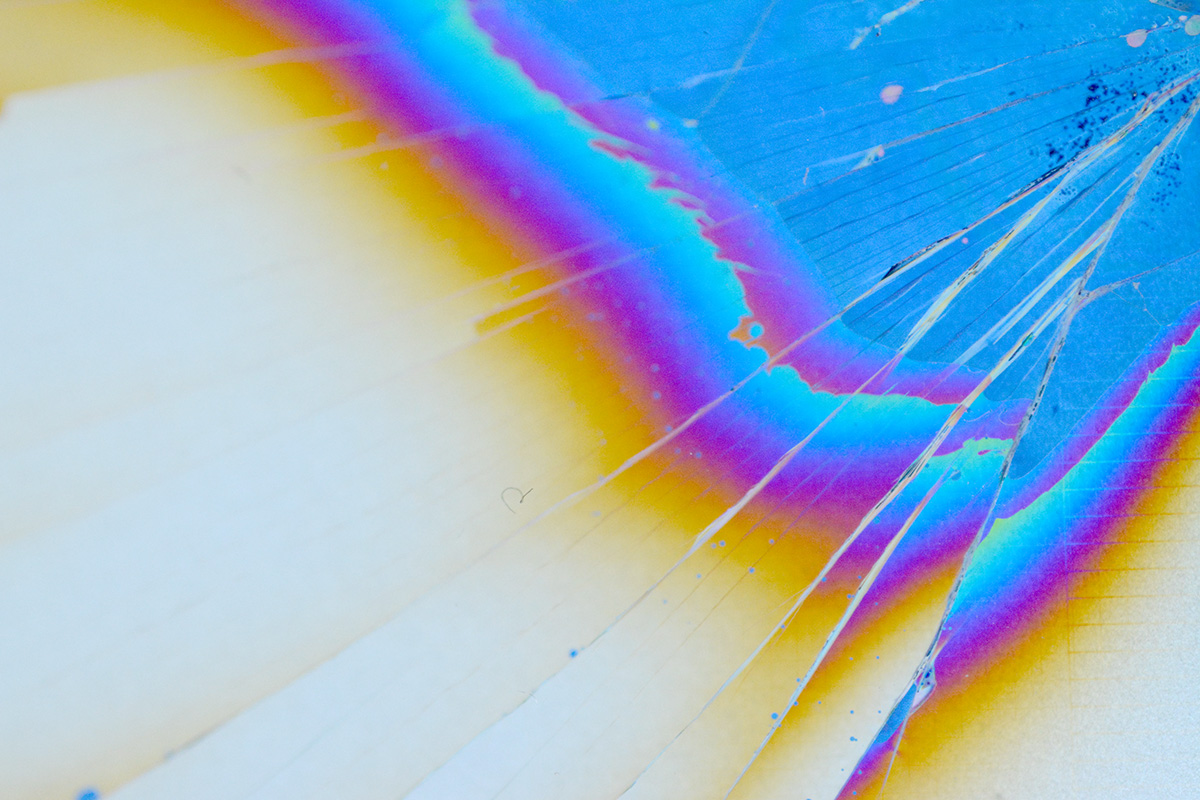

Another avenue I've idly explored is to repurpose liquid crystal effects. Take an ordinary monochrome LCD, and twist it until the glass cracks. The liquid crystal leaks out and the resulting interference effects create rainbow colours.

This is a macro shot of an LCD, the square grid is the pixel size (it was quite a low resolution screen), the arcs are cracks in the glass. The colours have not been enhanced. The blobs are the liquid crystal, and as you manipulate the display, especially if you squeeze it, the blobs move around and change colours.

It's great fun the play with, and I feel like it could be combined with a kaleidoscope for an even trippier experience. Perhaps a polarising ring that can be rotated.

So many ideas – but that's not what today's project is about. For there's another category we need to investigate: the admittedly mundane non-interactive "electronic" jewellery.

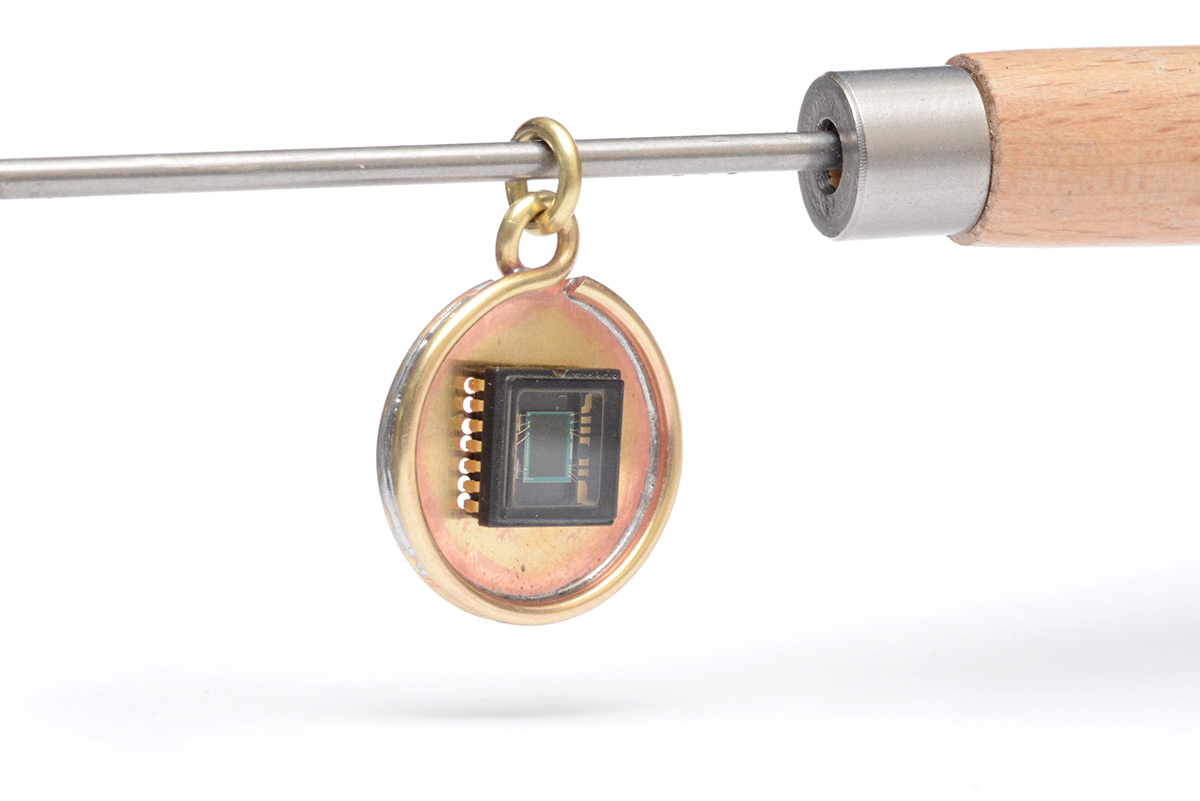

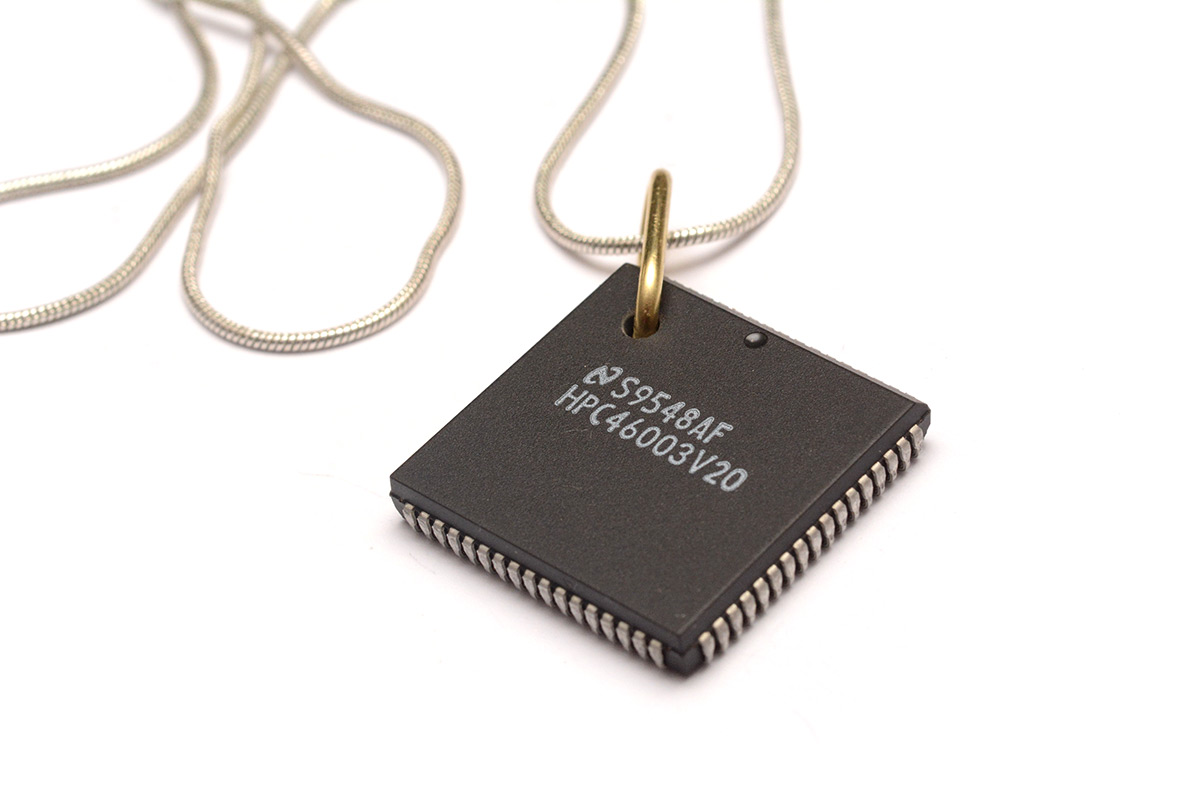

We've been doing this for a while, and I concede that it usually isn't interesting enough to warrant posting. A single drill hole and an oval jump ring turned this ancient microcontroller into a necklace:

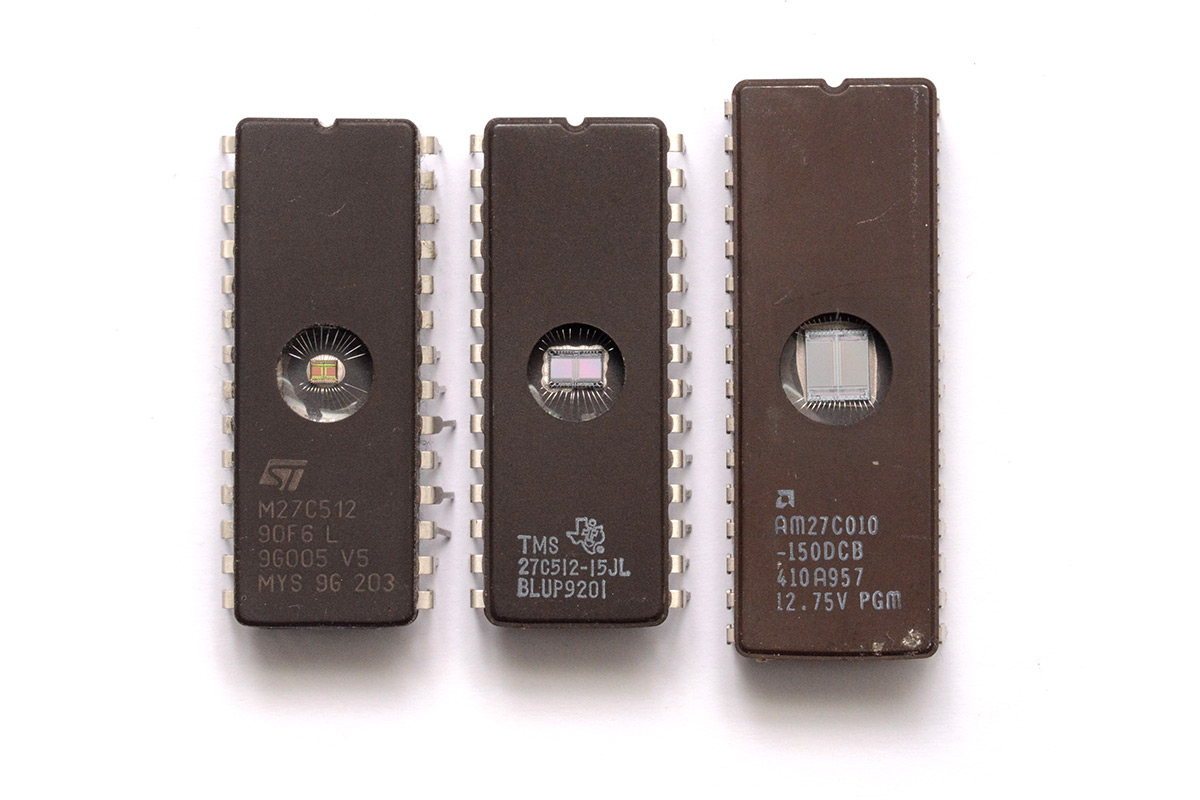

I have a shelf of interesting salvaged electronics kept only for their aesthetic value. I doubt I'll ever use any of the UV-erasable EPROM chips, but they're pretty cool to look at.

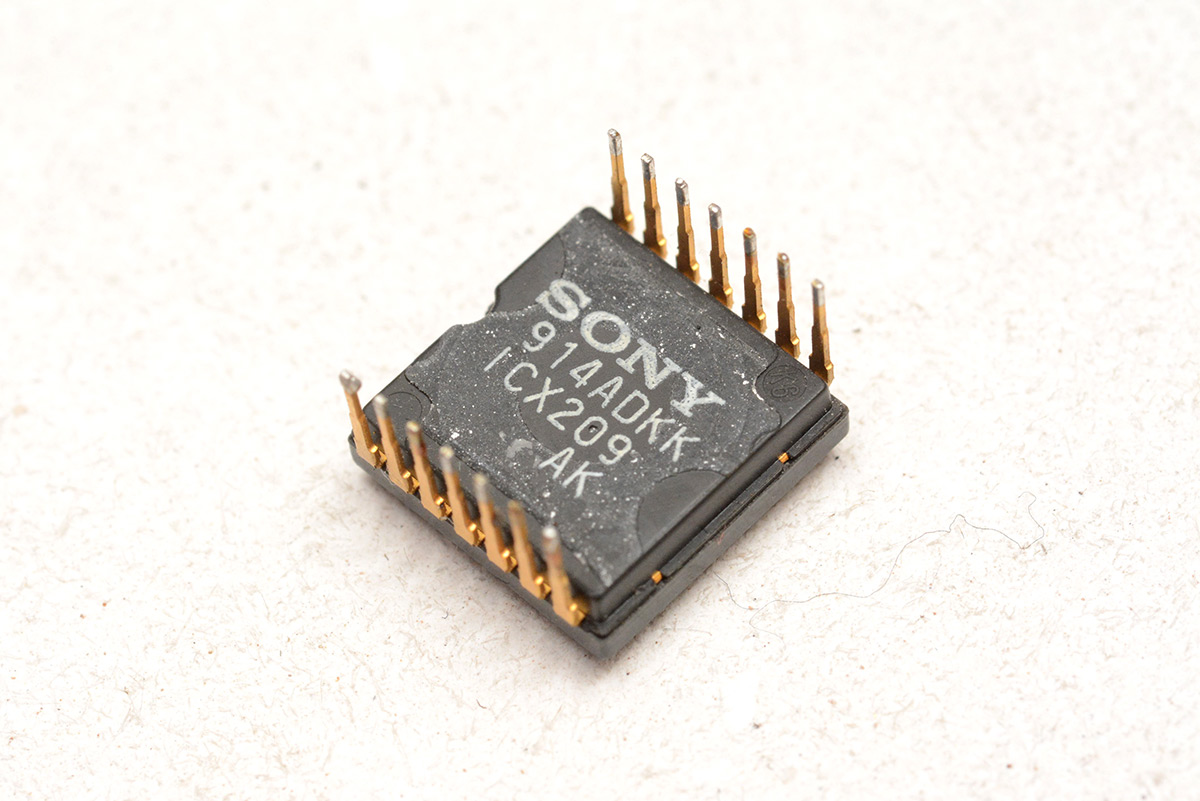

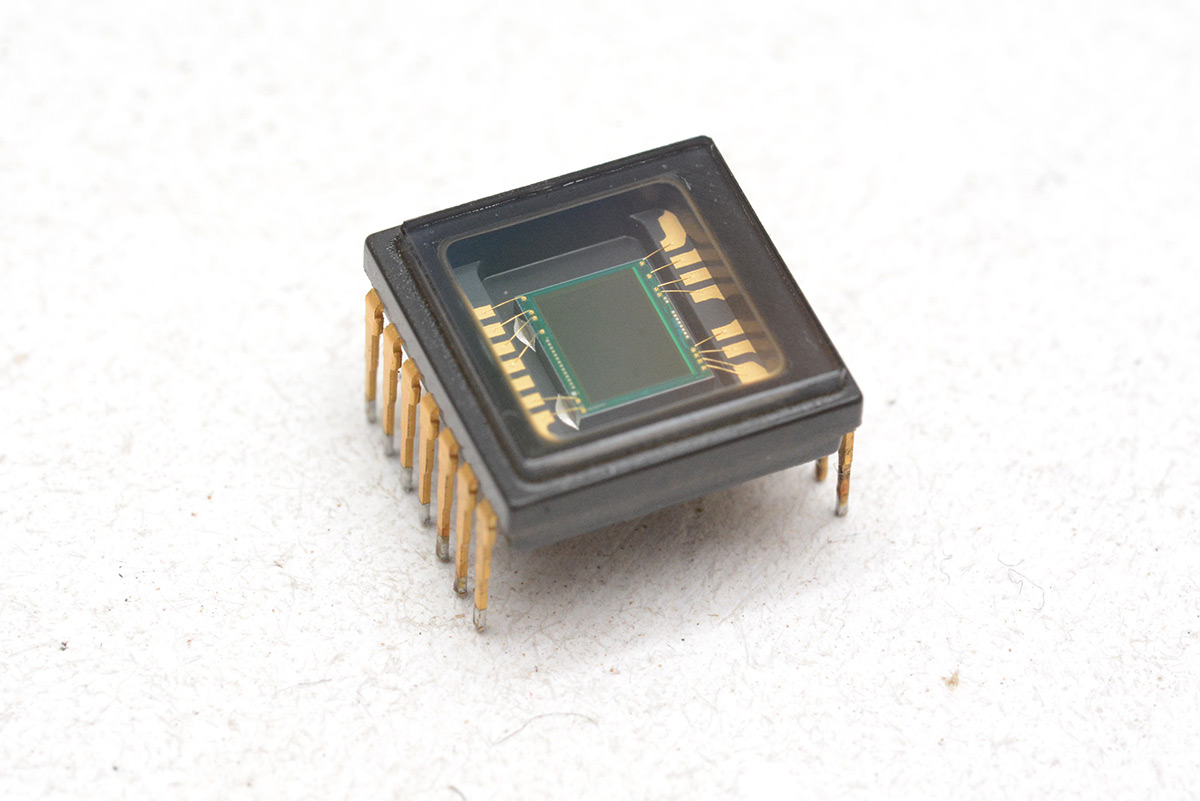

The huge DIP packages make them unsuitable for use in jewellery, but one component in that container has been calling out to me for a while, it's a CCD sensor from an old CCTV camera.

From that unique era of technology where a through-mount CCD sensor somehow made sense. The pin pitch is 1.27mm and the top surface has a bonded glass window. There was also an IR-cut filter that mounted onto the top of it.

It's been gathering dust for some time.

I've been trying to gain more experience with more traditional jewellery making techniques. Unlike most of my metalwork, goldsmithing and silversmithing are very handwavy. Dimensions generally don't matter, things are made to fit. Jewellers don't use milling machines or digital calipers, but they do bend a lot of wire and work with their hands.

A lot of jewellery tutorials feature pendant-motors with flexshafts, perhaps I need to invest in one – but I've got the cheap rotary tool so we can probably survive without. The concept of "soldering" is different in the jewellery world, and is something more like what I'd describe as brazing. A good jeweller will make their own "solder" by mixing up a lower melting point alloy that's colour-matched to the material they're working with.

I think there's some artistic merit in mounting old electronics as modern gemstones in jewellery, aside from their visual interest. The link between traditionally valued sparkly crystals and semiconductors is more than coincidental. Ruby and sapphire, for instance, are chemically almost identical (mostly aluminium oxide) but the trace impurities in their crystal structures control how they affect light. The study of these effects is what led to semiconductors and all of solid state physics.

I could flesh out the idea further, but really I'm just looking to get more jewellery practice.

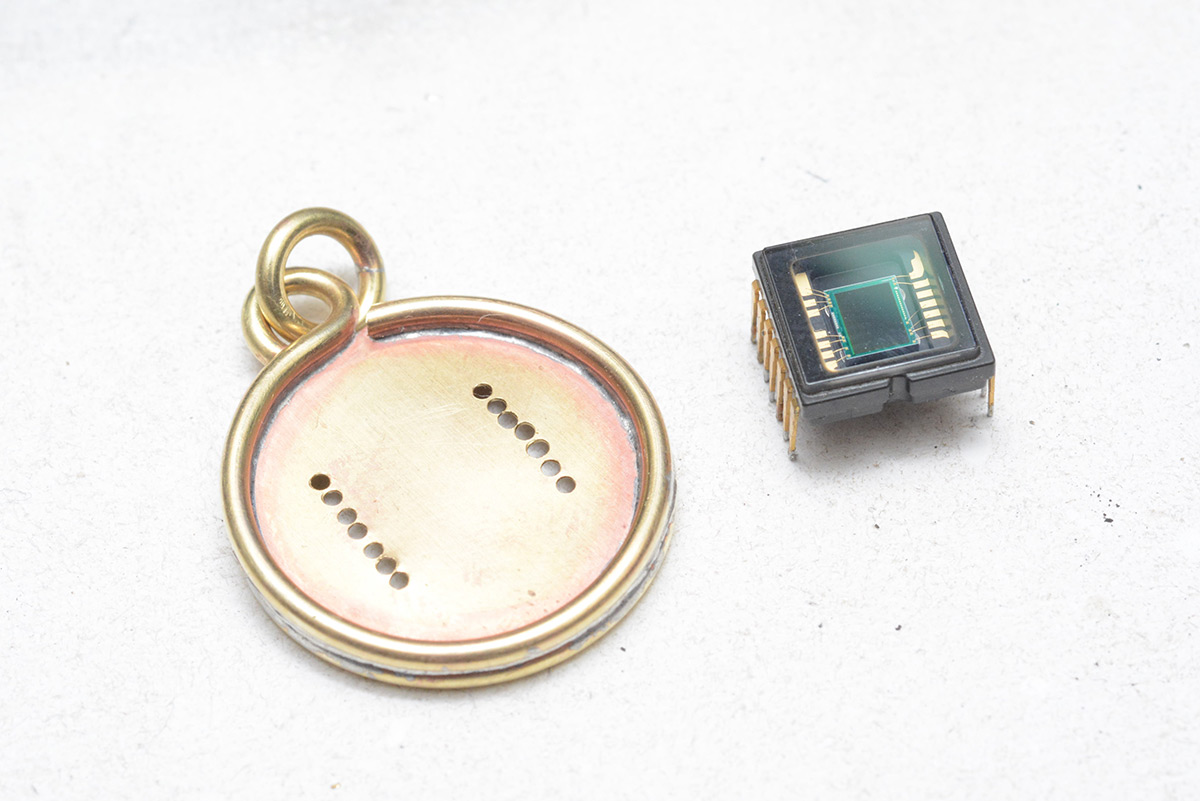

I started by bending some brass wire into the necklace body shape.

I consider myself quite good at bending wire, but this was quite a tricky shape to achieve. I wanted the ring at the top to hang it from, and the double loop to be the perimeter of the necklace. The goal was to get the two loops to perfectly circular, flat, and under tension with each other.

It took a few attempts to get it right. The wire is 1.5mm diameter, the necklace is about 22mm wide. The ends of the wire were cut with a jeweller's saw, and I probably could have been more precise with my cuts.

I then slid some brass shim stock between the two rings. It's held firmly in place, allowing me to trim around the edge with some scissors. We'll tidy it up later.

I slathered this in flux and decided to solder it with regular electronics solder. It's not that I'm afraid of the jeweller's solder, but it does use a much higher temperature that both anneals and discolours the material.

I heated it with the hot-air gun and poked it with solder from the outside until a clear fillet of solder appeared on the inside.

This is sitting on a compressed charcoal tile. It's apparently the right thing to use for jewellery soldering as it creates a reducing atmosphere. I wouldn't think this makes much difference when using the electric heat gun though.

Flipping the necklace over, the underside seems to have flowed perfectly. I'm not sure what the dark circle left behind on the charcoal means: did it, in fact, reduce the atmosphere? Who could say.

I added a jump ring. I'm now a dab hand at making little jump rings. I bent it through the attachment loop, then hung it over the side of the block and soldered it, again with electronics solder. After a little polishing, the joint is about as unobtrusive as we could hope for.

I probably should have trimmed the shim stock to final size before soldering. I ran around the edge with a razor blade and cleaned it up a bit, but the fillet is quite inconsistent because of the varying stickout. Also, when I tried to polish it, the groves around the perimeter are now perfect to trap all the polishing crud that accumulates. It does lead to a certain gritty aesthetic, but it's not what I was going for, so I tediously cleaned out the grooves again.

For the inner surface, I didn't polish away the red tint that comes from the flux, I think it adds some nice contrast.

To mount the IC, I printed a little label with the footprint in a circle to help us get it centred.

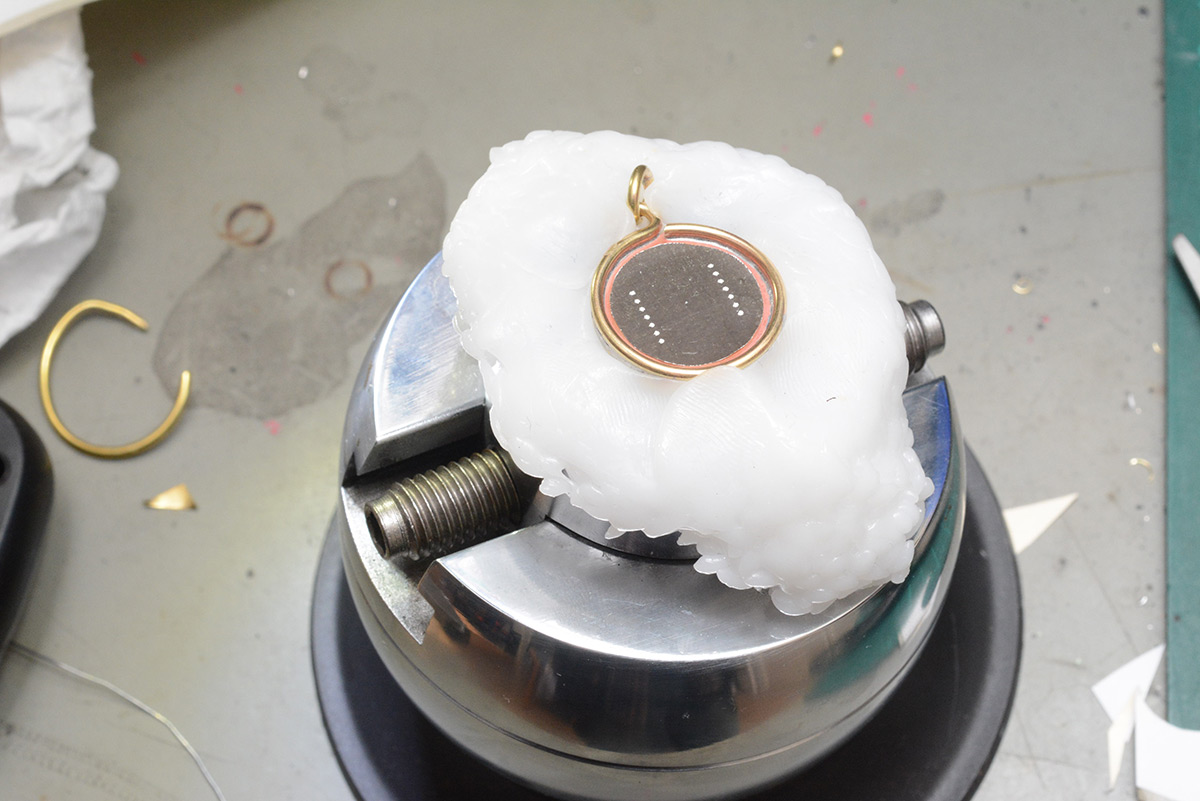

I should have also printed a cross to help align it vertically, but this will do. If we just went and drilled the holes, we risk denting or deforming the thin material (it's 5mil shim, so 0.127mm thick). I've been doing a bit of research and one way to hold awkward bits of jewellery is to use polymorph plastic. It's known by a few names, you melt the pellets in hot water and they become mouldable, then turn hard at room temperature.

I stuck the necklace onto the top of my fairly new engraver's block / ball vice. It was very cheap.

I then poked each hole through with the dremel tool and a PCB drill. Remember, this is jewellery, not a circuit board. The uneven result is part of the handmade aesthetic.

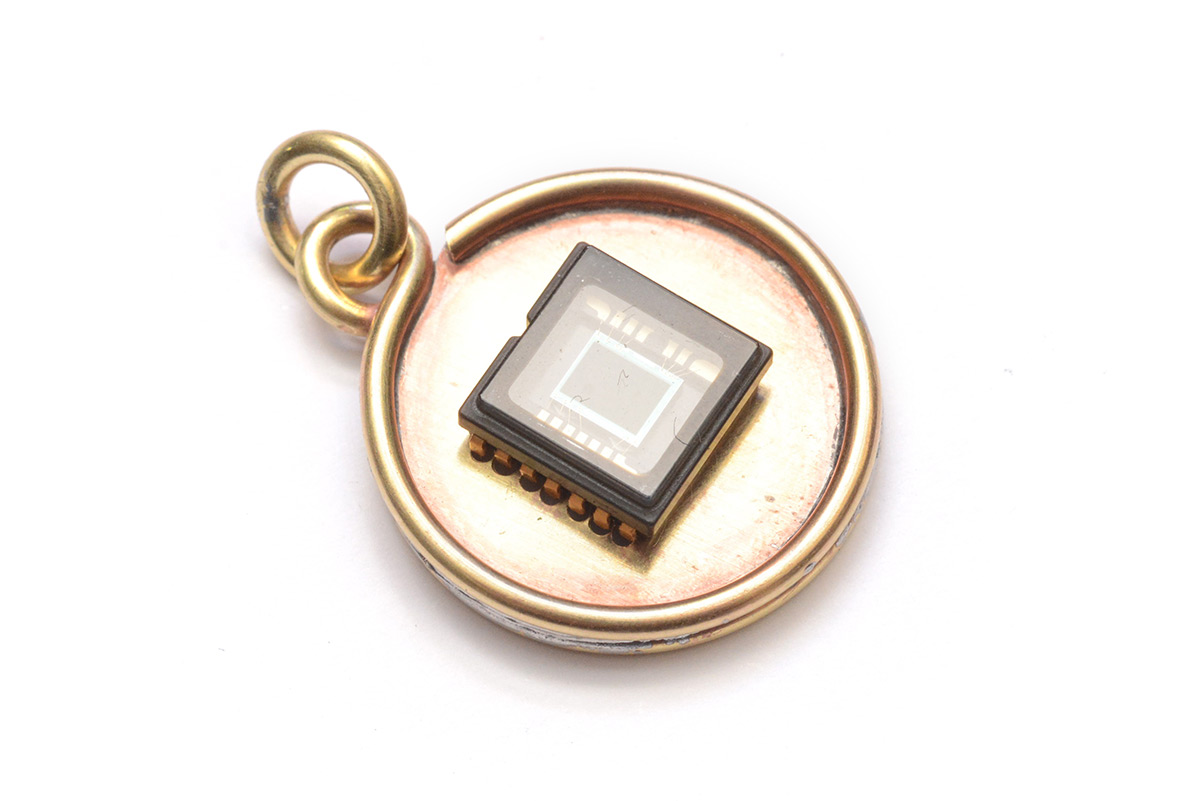

I was unsure how to finish this fitting.

I ended up just folding the legs over. The back of the necklace is not particularly pretty. I suppose it doesn't matter, the important thing is to not have spiky bits that could catch on clothes. Potentially we could stick something else on the back.

Whatever. I'm gonna call that done.

It's not my most impressive work, but it didn't take long and we're just trying to gain some practice here. I'll no doubt make a load more trinkets in the same vein.