| tjookum | Posted: 25 Apr 2025, 02:14 PM |

|---|---|

|

Member Posts: 5 Joined: 25-April 25 |

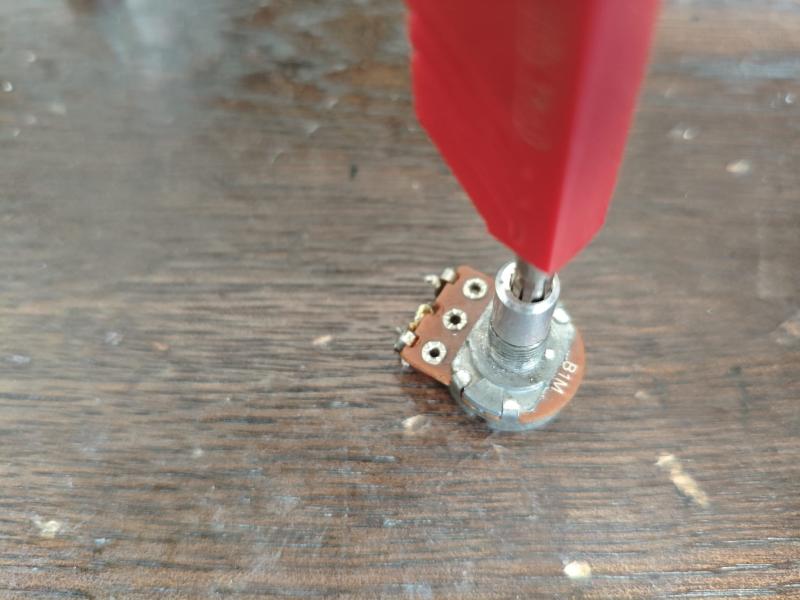

First post here, long time enjoyer of your videos and projects. Truly a unique mind and always a joy to see you solve your self inflicted problems. Anyway, I saw your video yesterday about the beautifully executed eurorack knob. It really struck home with me, besides the space saving it would be much more intuitive and fun to just be able to use CV for any knob. I've been designing and building a custom modular synth from the ground up based on those same principles of intuitive control and fun. Well, after I saw your lovely complex solution an idea came to mind. The main thing is that you would need coaxial spinning connector to conform to the 3.5mm eurorack standard. But with the (in my eyes far superior) banana jack you could just have a hole in the pot and use the shaft/body as the socket. A quick and dirty test with a 4mm (awfully offcentre) hole in a 6.35mm standard pot and it works like a dream. The depth has to be quite shallow but with another hole in a knob it has a satisfying feel and is really solid. Not elegant but I hope this idea can inspire you to make that synth without breaking the bank. If you or anyone else is interested in my not yet released new modular format let me know! Would love to do a collaboration. As always, keep doing what you do. Jochem         ------------- |

| [top] | |

| mit | Posted: 26 Apr 2025, 09:51 AM |

|

yeah whatever Admin Posts: 658 Joined: 4-May 16 |

Oh gosh, that is a remarkably simple solution! My first thought was that the shaft would have an electrical connection to the wiper, but of course that doesn't make sense as you'd never be able to panel mount them to a metal case if the shafts weren't electrically isolated. In this case you could use a PCB as the front panel, and have a big plated hole to form the connection. The only downside is that with banana leads, you would need to have VERY good grounding to maintain signal integrity. Power is normally supplied to modules on little IDC ribbon cables. If there's even a fraction of an ohm on the return current path, there will be a voltage difference between grounds and this will affect the apparent signal on the patch cable. In a metal case, it might be enough to use the metal frame as a big grounded bus bar. Worth noting that you can get mini banana leads, just 2mm diameter, though they may be a bit delicate. Unrelated, but one of the other ideas I considered and forgot to mention was to use a standard socket, and place a potentiometer physically behind it, with a mechanical linkage to a hollow knob that sits around the socket. ------------- |

| [top] | |

| tjookum | Posted: 26 Apr 2025, 04:59 PM |

|

Member Posts: 5 Joined: 25-April 25 |

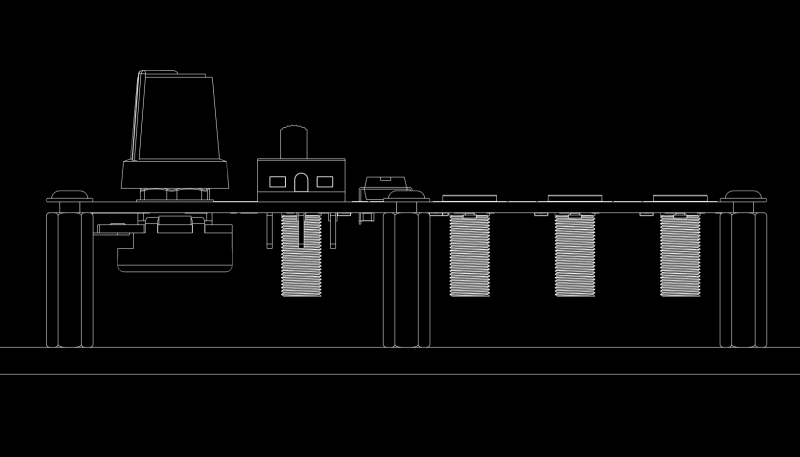

Thanks for your reply. And yeah, without your little nudge in the right direction I would have never have thought of it. And yes, standard pot shafts are always isolated so the shaft and mounting flange in my prototype function like a regular banana socket. A quick test with my multimeter confirms that it barely adds any extra resistance over the test lead itself. I measured 1.0 ohms without and 1.1 ohms with the pot which falls well within measurement error. The whole reason for designing my own system from the ground up is that I wanted to specifically get away from the quirks and limitations of eurorack. I have designed it with banana connectors in mind so the connectors as well as all the other components are directly mounted to the pcb. All the pcb's form a grid wich is tied directly to a metal backplate, forming a sandwich construction and I haven't had any issues with grounding. And I also don't think signal integrity is a big factor when we talk about modular synthesizer frequency's and voltage swing. Don't get me wrong, I specifically design my pcb's with signal integrity in mind but Im pretty sure that's mainly for my own peace of mind. At least for the analog side of things we are talking max 20khz and 10vPP. I know about the 2mm banana jacks and I initially tried to use those but they seemed fiddly and fragile. Like you mentioned in the video, the whole idea of modular is to have something physical to help with creating music. Although I must admit, the 4mm hole is cutting it very close with the 6mm shaft. I don't have access to a lathe but that would make the process very precise and repeatable. If it's ok with you I can post a link to the (semi finished) website of the modular I'm working on. Here is a little technical side view which should give you an idea.  I'll try to incorporate a more polished version of the banana knob in the next batch of modules. p.s. AlPS do make some rather expensive looking ring encoders: https://tech.alpsalpine.com/e/products/category/encorders/sub/04/ I did consider those at one point but they seem very overpriced and bulky, food for thought though. ------------- |

| [top] | |

| mit | Posted: 27 Apr 2025, 09:56 AM |

|

yeah whatever Admin Posts: 658 Joined: 4-May 16 |

Yeah grounding is much more of an issue when you have a string of eurorack modules getting power through a flimsy ribbon cable. It might not be a problem if all the modules are analog, but if you have a digital module with a microcontroller, it can create an audible buzz that works its way into the sound output. I wonder how well the aluminium socket will hold up, if it will oxidise over time. I'm also curious to find out what the connection is like while the knob is rotated. Presumably the shaft and the body have some grease between them, does this change the resistance while it's turned? QUOTE

Sure feel free to share it.If it's ok with you I can post a link to the (semi finished) website of the modular I'm working on. ------------- |

| [top] | |

| tjookum | Posted: 29 Apr 2025, 11:02 AM |

|

Member Posts: 5 Joined: 25-April 25 |

QUOTE

Totally agree, and with modules becoming more and more digital in nature the noise can get out of hand quick. Yeah grounding is much more of an issue when you have a string of eurorack modules getting power through a flimsy ribbon cable. It might not be a problem if all the modules are analog, but if you have a digital module with a microcontroller, it can create an audible buzz that works its way into the sound output. QUOTE

I decided to sacrifice one pot to the teardown gods.I wonder how well the aluminium socket will hold up, if it will oxidise over time. I'm also curious to find out what the connection is like while the knob is rotated. Presumably the shaft and the body have some grease between them, does this change the resistance while it's turned?  You can clearly see that the central shaft is fully isolated from the wiper.   As you can see, the inner shaft is around 4mm and with the badly centered drill I got kind of lucky with just enough metal to keep the shaft intact. This might also explain the readings I got as the bananajack springs were making direct contact with the housing for at least half of the hole. And you are correct about the grease, any amount of wiggle or play will result in a intermittent connection but because of the large contact patch between the shaft and the barrel I suspect it won't be much of a problem. The aluminium on these ALPHA branded pots seems of very low quality so corrosion might also become an issue. Unfortunately this means that in practice the 4mm hole in the top of the pot can only be around 8mm deep for this style of pot which isn't enough for proper engagement. Searching for longer shaft pots and drilling a perfectly centered hole might defeat the purpose of this being a simpler solution :/. I still really like the idea and I'm sure the issues I mentioned can be fixed. Your other solution with the linkage would also be greatly simplified when using banana sockets so I might look into that some more. Either way I will work on it some more and try to incorporate it in some modules to test if the idea is valid. You can find more info on the mosaic modular system Im designing here: https://mosaicsynth.com/index.php/system-info/ If you have any questions, feel free to contact me here or through my website. ------------- |

| [top] | |

| mit | Posted: 1 May 2025, 10:20 AM |

|

yeah whatever Admin Posts: 658 Joined: 4-May 16 |

That's super interesting, thanks for sharing. I can think of a few ways it could still work, maybe extending the shaft or producing a new one from a CNC service with the socket already formed, but none are as simple as the original idea. The mosaic system looks neat! ------------- |

| [top] | |

| tjookum | Posted: 4 May 2025, 08:26 AM |

|

Member Posts: 5 Joined: 25-April 25 |

Thanks! And yeah, replacing the shaft with a custom made one would be the ultimate solution. A bit of knurling and you wouldn't even need a knob. ------------- |

| [top] | |

| Rachel | Posted: 6 May 2025, 10:12 PM |

|

potato Member Posts: 4 Joined: 28-March 24 |

Sometimes I want to keep you all as pets. This is a very cute interaction -------------  |

| [top] | |

| tjookum | Posted: 12 May 2025, 07:49 AM |

|

Member Posts: 5 Joined: 25-April 25 |

Hahaha, that comment made my day. ------------- |

| [top] | |

Sign in to post a reply.